Quality Wheel Rims

Quality is being controlled through strict quality control measures which are taken by qualified & well trained staff & operators, specially designed gauges & precession instruments & with the use of High Tech Machinery

SAZGAR is capable of designing and developing Molds, Tools, Jugs and Fixtures of all types for sheet metal components in a relatively short span of time.

The plant has been established with a combination of local and imported machinery which can be broadly classified as below:

- Shearing machines having shearing capacity upto 12.00 mm.

- Most Modern CNC Flash Butt Welder of 650 kva and 750 kva capacity

- • Wheel Rim rolling machines having rim rolling capacity up to 15″ x 30″.

- Presses ranging from micro to triple action hydraulic presses up to 600 MTN.

- Poweder coating paint shop with seven stage spray system pretreatment and baking oven.

- Complete assembly line.

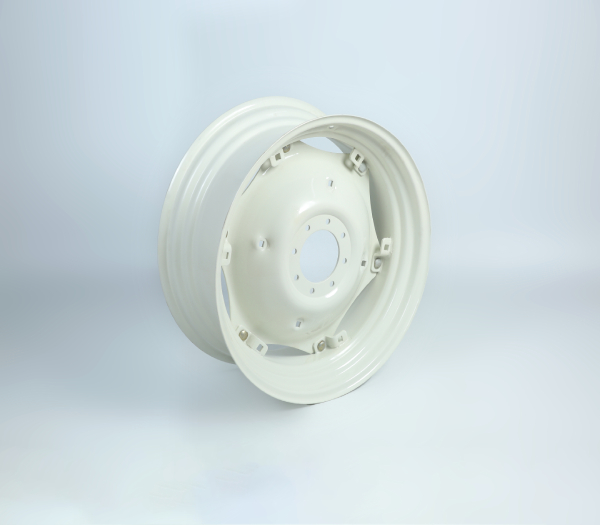

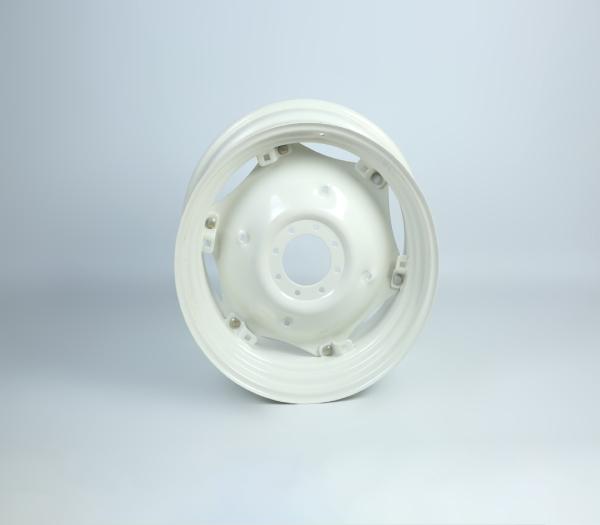

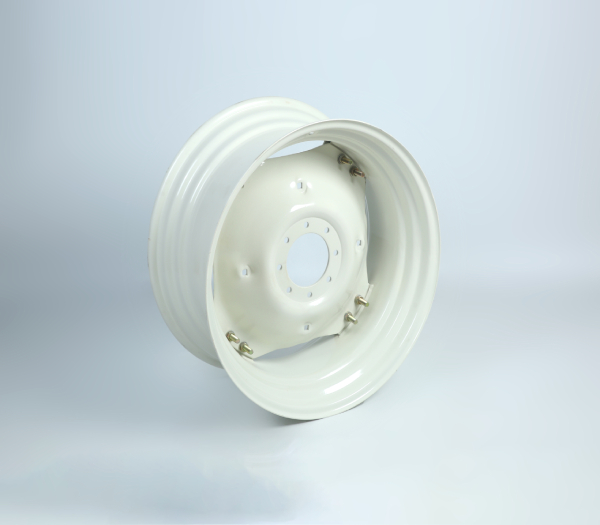

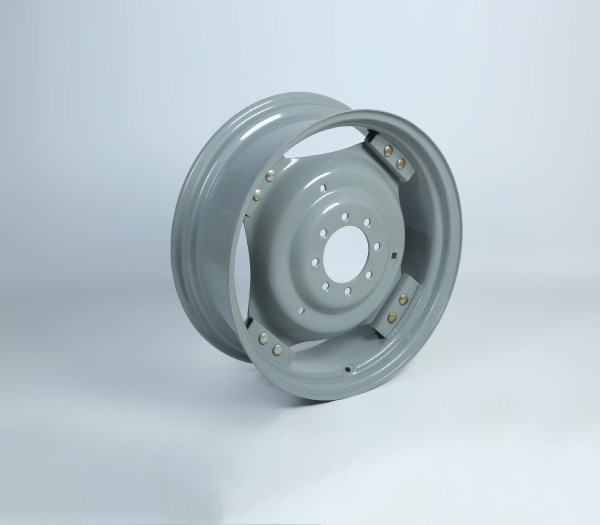

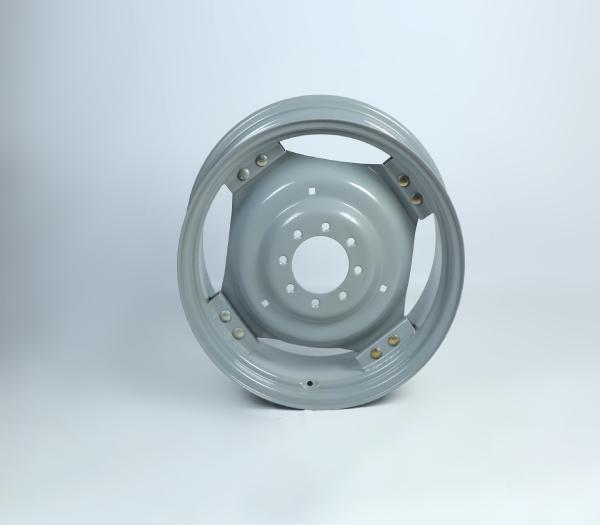

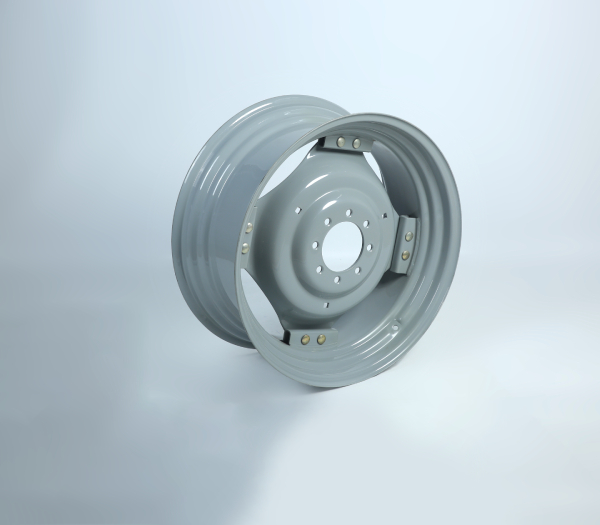

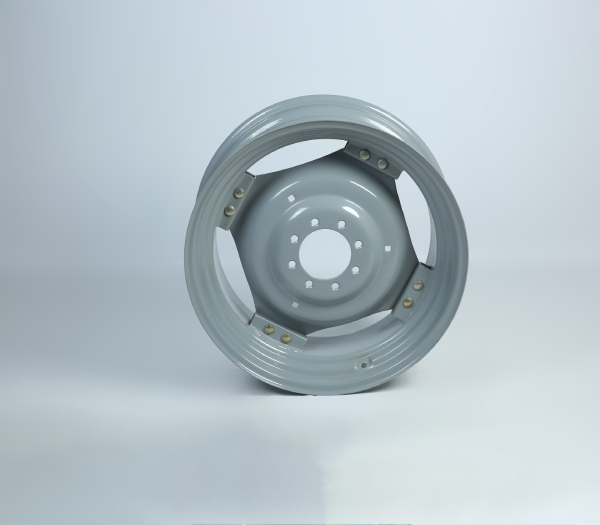

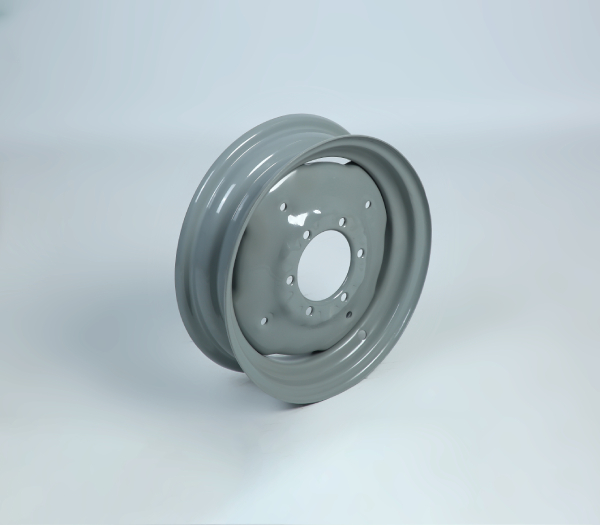

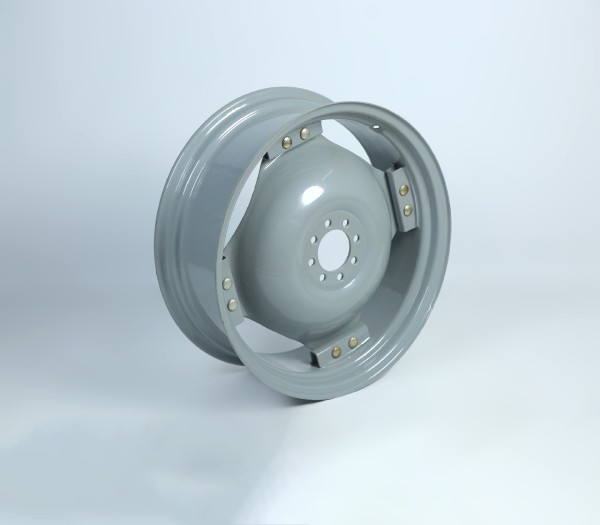

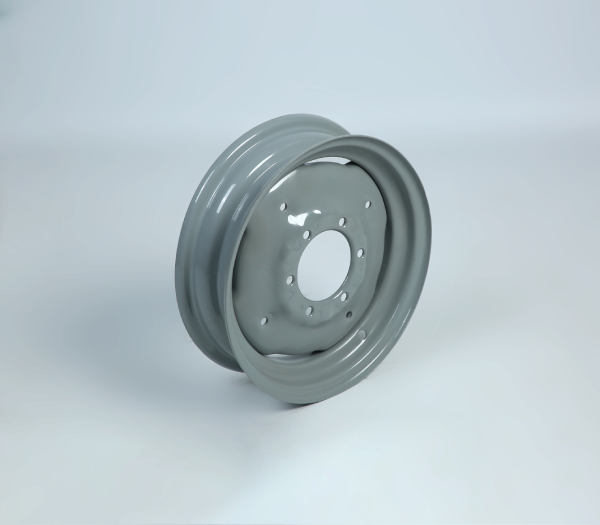

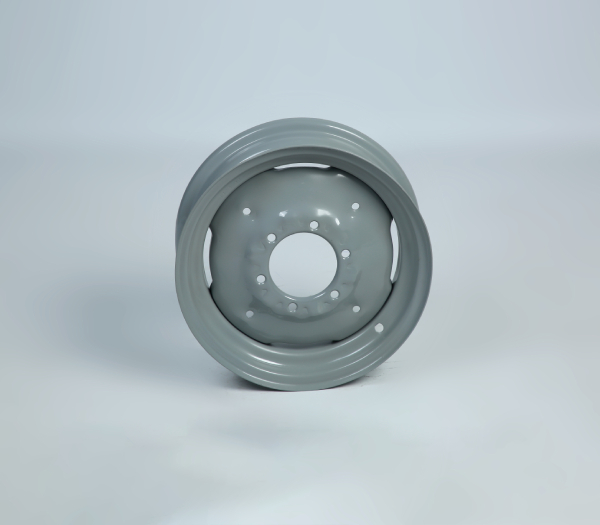

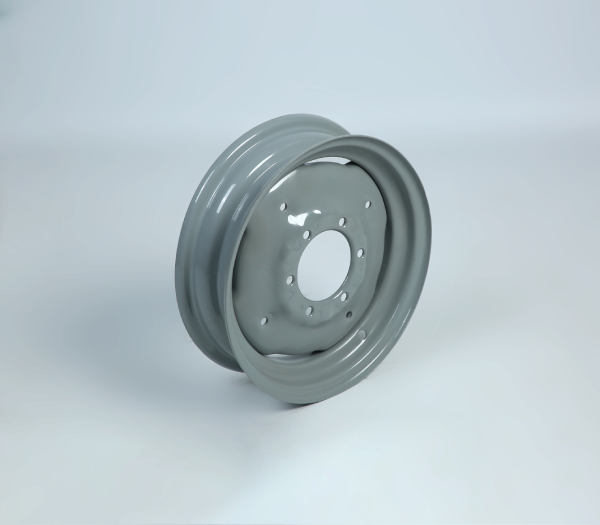

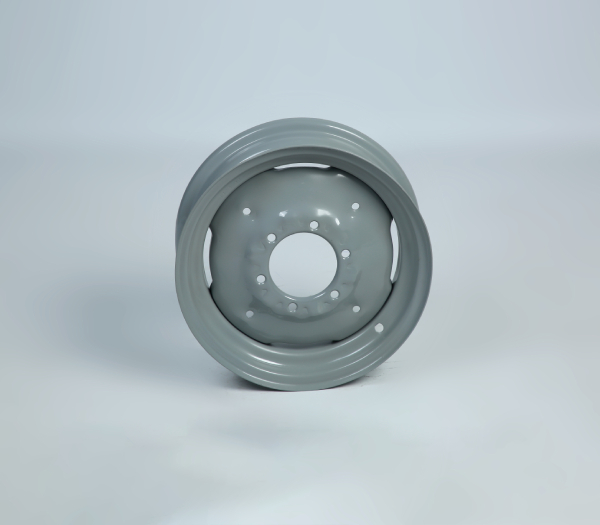

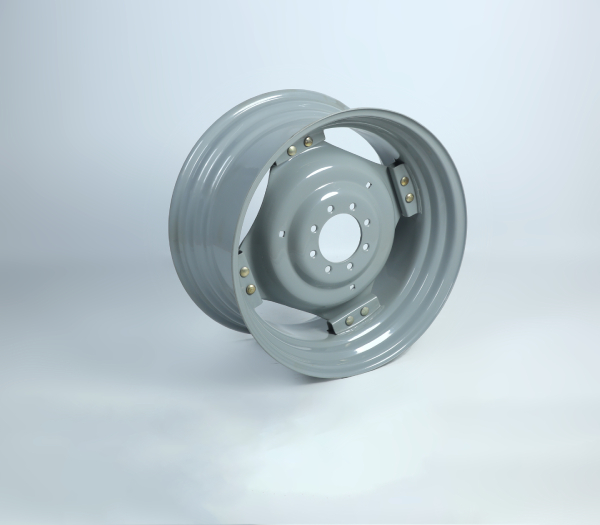

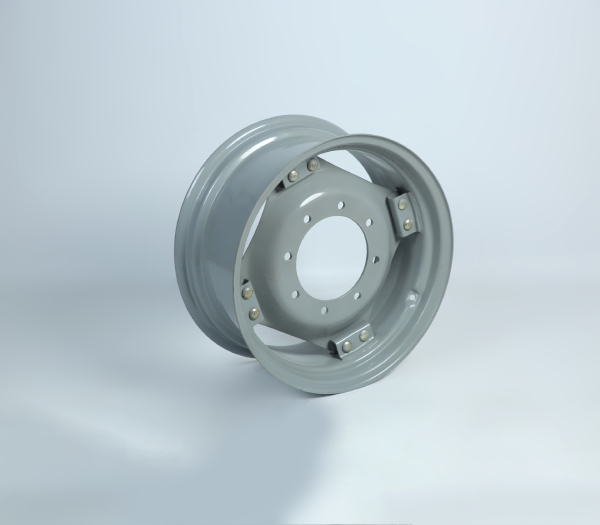

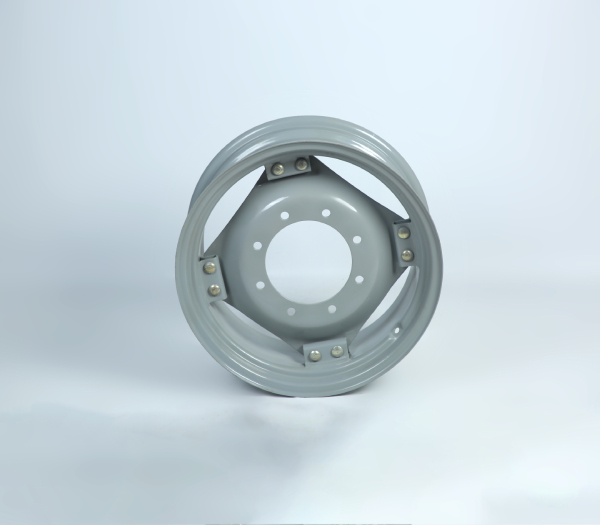

FIAT RIMS

MASSEY RIMS

MASSEY FERGUSON-240

Rim Front 240

MASSEY FERGUSON-240

Rim Rear 240

MASSEY ferguson-260

Rim Front 260

MASSEY-ferguson-385

Rim Front 385

MASSEY-ferguson-385

Rim Rear 385

MASSEY-ferguson-385

Rim Front 385 4WD